6.2. Example – Heat Transfer#

Introduction#

Fire Dynamics Simulator (FDS) calculates the mechanisms of heat transfer taking into account the corresponding physical processes of convection and radiation. From the resulting heat flux onto a solid surface, the surface temperature as well as the temperature at a certain depth can be determined, depending on the material properties and the the respective boundary conditions. By default, FDS only performs a transient, one-dimensional calculation of heat transfer. The objective of this exercise is to discuss the different influences of radiation and convection as well as the surface and material properties of a solid body on its heating in case of fire. The HeatTransfer.fds input file should be used as a starting point.

Setup#

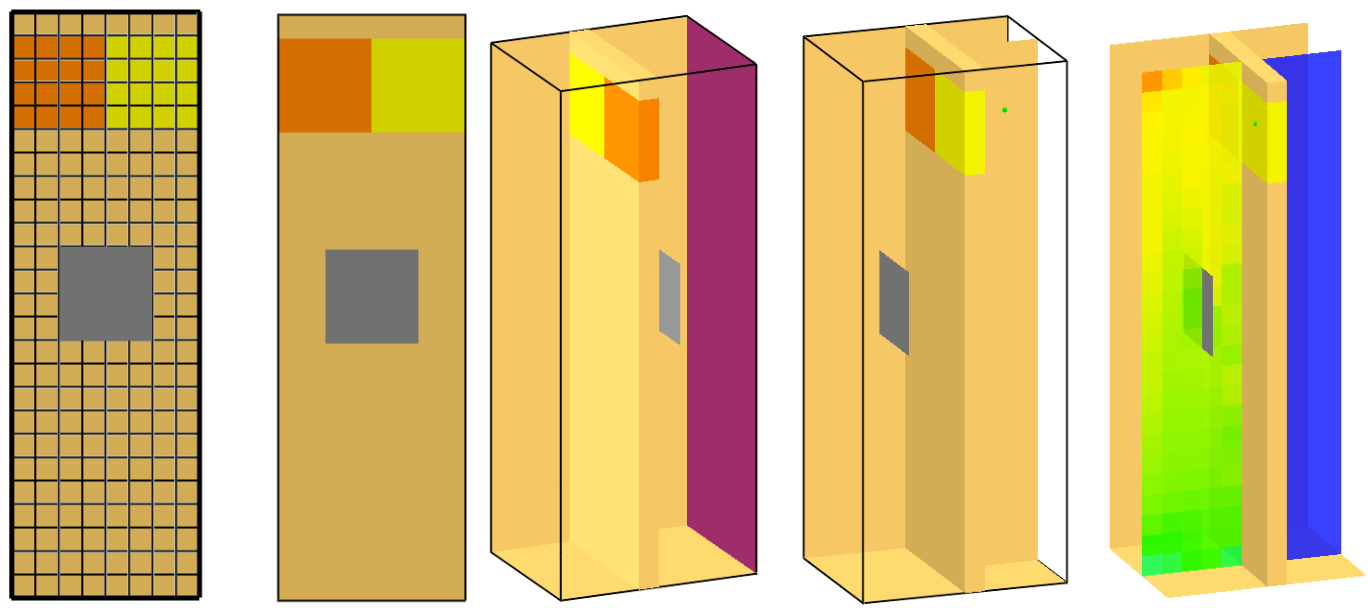

The extension of the computational domain is

Fig. 6.15 SMV visualization of the geometry. The surface patch HEATER, which has a constant surface temperature of \(1000^\circ C\) (TMP_FRONT = 1000) ,is colored reddish. The orange and yellow obstructions (OBST) depict different surfaces (SURF). The gray heat shield covers thermocouples and devices from a radiative impact.#

Heat Flux#

FDS provides several output quantities related to the thermal exposure of solid surfaces (See section 21.10.7 FDS User’s Guide).

The sum of radiative and convective energy absorbed at a solid surface is expressed by the TOTAL HEAT FLUX or NET HEAT FLUX:

where \(\mf \dot{q}_{\rm inc,rad}\) is the incident radiative heat flux (INCIDENT HEAT FLUX), \(\mf \epsilon_{\rm s}\) is the surface emissivity, h is the convective heat transfer coefficient, \(\mf T_{\rm s}\) is the surface temperature, and \(\mf T_{\rm gas}\) is the gas temperature in the vicinity of the surface. The convective heat transfer coefficient, h, is calculated by FDS using the specified surface properties and the calculated near-boundary flow characteristics.

The radiative component can be evaluated separately by the RADIATIVE HEAT FLUX quantity:

The convective component is given by CONVECTIVE HEAT FLUX:

The heat flux on a component depends on its surface temperature, which is automatically calculated by FDS. The heat flux on a component with a predefined temperature, e.g. a water-cooled heat flux gauge can be evaluated by GAUGE HEAT FLUX. If not explicitly defined, \(\mf T_{gauge}\) is assumed to be equal to the ambient temperature.

Quantities on a solid obstruction can be recorded using the BNDF namelist group. It can be defined similar to SLCF like:

&BNDF QUANTITY='NET HEAT FLUX', CELL_CENTERED=.TRUE. /

For more detailed information on how to set up BNDF in FDS please refer to section 21.5 FDS User’s Guide.

By default, the specified quantities are evaluated for the surfaces of all obstructions as well as the boundaries of the computational domain. You can prevent this with the parameter BNDF_DEFAULT = .FALSE. on the MISC line. Individual obstructions can then be turned back on with BNDF_OBST=.TRUE. on the appropriate OBST line.

import fdsreader

from fdsreader.bndf.utils import sort_patches_cartesian

import numpy as np

import matplotlib.pyplot as plt

plt.rcParams['lines.linewidth'] = 1

root = '../../../../'

data_root = root + 'data/heat_transfer/HeatTransfer_0'

sim = fdsreader.Simulation(data_root)

def get_bndf_face(quantity, obstruction=0, orientation=-2):

obst = sim.obstructions[0]

patches = list()

for sub_obst in obst.filter_by_orientation(orientation):

# Get boundary data for a specific quantity

sub_obst_data = sub_obst.get_data(quantity)

patches.append(sub_obst_data.data[orientation])

# Combine patches to a single face for plotting

patches = sort_patches_cartesian(patches)

shape_dim1 = sum([patch_row[0].shape[0] for patch_row in patches])

shape_dim2 = sum([patch.shape[1] for patch in patches[0]])

n_t = patches[0][0].n_t # Number of timesteps

face = np.empty(shape=(n_t, shape_dim1, shape_dim2))

dim1_pos = 0

dim2_pos = 0

for patch_row in patches:

d1 = patch_row[0].shape[0]

for patch in patch_row:

d2 = patch.shape[1]

face[:, dim1_pos:dim1_pos + d1,

dim2_pos:dim2_pos + d2] = patch.data

dim2_pos += d2

dim1_pos += d1

dim2_pos = 0

return face

total_hf = get_bndf_face('TOTAL HEAT FLUX')

convective_hf = get_bndf_face('CONVECTIVE HEAT FLUX')

radiative_hf = get_bndf_face('RADIATIVE HEAT FLUX')

gauge_hf = get_bndf_face('GAUGE HEAT FLUX')

incident_hf = get_bndf_face('INCIDENT HEAT FLUX')

vmin = 0

vmax = 80

fig, (ax1, ax2, ax3, ax4, ax5) = plt.subplots(1,5,figsize=(15,30), sharey=True)

heatmap = ax1.imshow(total_hf[500].T, vmin=vmin, vmax=vmax, origin="lower", cmap="jet")

ax2.imshow(convective_hf[500].T, vmin=vmin, vmax=vmax, origin="lower", cmap="jet")

ax3.imshow(radiative_hf[500].T, vmin=vmin, vmax=vmax, origin="lower", cmap="jet")

ax4.imshow(incident_hf[500].T, vmin=vmin, vmax=vmax, origin="lower", cmap="jet")

ax5.imshow(gauge_hf[500].T, vmin=vmin, vmax=vmax, origin="lower", cmap="jet")

ax1.set_title("TOTAL HEAT FLUX")

ax2.set_title("CONVECTIVE HEAT FLUX")

ax3.set_title("RADIATIVE HEAT FLUX")

ax4.set_title("GAUGE HEAT FLUX")

ax5.set_title("INCIDENT HEAT FLUX")

ax1.set_xlabel("$n_{cells}~X$")

ax2.set_xlabel("$n_{cells}~X$")

ax3.set_xlabel("$n_{cells}~X$")

ax4.set_xlabel("$n_{cells}~X$")

ax5.set_xlabel("$n_{cells}~X$")

ax1.set_ylabel("$n_{cells}~Y$")

fig.subplots_adjust(right=0.83)

cbar_ax = fig.add_axes([0.85, 0.41, 0.02, 0.185])

cbar_ax.set_title('$kW / m^2$')

fig.colorbar(heatmap, cax=cbar_ax)

# ax5.colorbar(label="Temperature / $\sf ^\circ C$")

# plt.xlabel("$\sf N_{cells,x}$ / -")

# plt.ylabel("$\sf N_{cells,y}$ / -")

fig.savefig('figs/heatflux_bndf.svg', bbox_inches='tight')

plt.close()

Fig. 6.16 TOTAL HEAT FLUX, CONVECTIVE HEAT FLUX, RADIATIVE HEAT FLUX, GAUGE HEAT FLUX and INCIDENT HEAT FLUX on a solid obstruction opposite a flat radiator with a constant temperature of \(\mf T = 1000^\circ C\)#

Task 1#

The local gas phase temperature at a certain cell can be evaluated via a simple DEVC with QUANTITY = 'TEMPERATURE'. The output of a thermocouple which lags the true gas temperature by an amount determined mainly by its size can be assessed by a DEVC with QUANTITY = THERMOCOUPLE. It takes into account the radiative and convective heat transfer to a small sphere. For this purpose, it must be assigned an emissivity and a diameter. The properties can be assigned to a DEVICE via the PROP_ID attribute (see also section 20.1 of FDS User’s Guide. For detailed information on how to model thermocouples in FDS please refer to section 21.10.6.

Tasks

Place simple devices with

QUANTITY = 'TEMPERATURE'andTHERMOCOUPLEat X = 0, Y = 0.8 and heights z = 0.6 m (bottom), 2.6 m (behind heat shield), 4.4 m (top). Run the simulation for at least 100 seconds and plot the temporal output of the devices. Discuss what effects lead to the differences between the two types of devices. For the thermocouples assume anEMISSIVITYof 0.9 and a diameter of d = 3 mm.

Fig. 6.17 Namelist dependencies DEVC (device) and PROP (property)#

data_root = root + 'data/heat_transfer/HeatTransfer_1'

sim = fdsreader.Simulation(data_root)

time = sim.devices['Time'].data

t_top = sim.devices['T_top'].data

tc_top = sim.devices['TC_top'].data

t_middle = sim.devices['T_middle'].data

tc_middle = sim.devices['TC_middle'].data

t_bottom = sim.devices['T_bottom'].data

tc_bottom = sim.devices['TC_bottom'].data

plt.plot(time, tc_top, label='Thermocouple top', color='red')

plt.plot(time, t_top, label='Temp Devc top', color='red', alpha=0.5 )

plt.plot(time, tc_middle, label='Thermocouple middle', color='green')

plt.plot(time, t_middle, label='Temp Devc middle', color='green', alpha=0.5)

plt.plot(time, tc_bottom, label='Thermocouple bottom',color='blue')

plt.plot(time, t_bottom, label='Temp Devc bottom', color='blue', alpha=0.5)

plt.xlabel("Time / s")

plt.ylabel("Temperature / $\circ C$")

plt.legend(loc='best')

plt.grid(True, linestyle='--', alpha=0.5)

plt.xlim(0,100)

plt.savefig('figs/thermocouples.svg', bbox_inches='tight')

plt.close()

1. Solution

Fig. 6.18 Measured temperature of THERMOCOUPLE and simple TEMPERATURE DEVC#

Task 2#

In order to correctly compute the heat transfer within a solid obstruction, the thermal material properties CONDUCTIVITY, SPECIF_HEAT and DENSITY must be known. A new material can be defined via the MATL attribute. The available parameters for describing the material properties can be found at section 22.14 of FDS User’s Guide). Another parameter influencing the heat conduction within a solid is its thermal effective THICKNESS. This is defined on the SURF line and is independent from the actual thickness of an obstruction.

The EMISSIVITY (default 0.9) can be set on the SURF or MATL line while the MATL parameter is given priority.

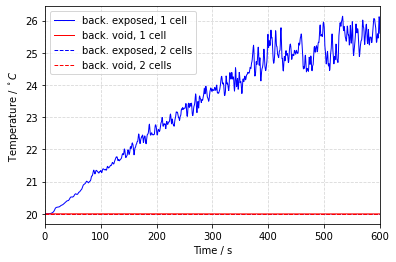

The back side boundary conditions of a solid obstruction can be defined on the SURF line as:

EXPOSED: Calculates heat conduction through the wall into the space behind the wall (default)INSULATED: Prevents any heat loss from the back side of the materialVOID: Always backs up to ambient temperature

Important

The THICKNESS of a SURF ought to be the actual thickness of the “wall” through which FDS performs a 1-D heat conduction calculation. It is independent from the mesh cell width. If the obstruction is on the boundary of the domain or is more than one cell thick, then it is automatically assumed to back up to an air gap at ambient temperature.

Fig. 6.19 Namelist dependencies OBST (obstruction), SURF (surface), and MATL (material)#

Tasks

Define a new material “Steel” with the following material properties \(\mf c_p = 0.5~kJ~/kg~K\), \(\mf \lambda = 45.3~W~/m~K \) and \(\mf \rho=7854~kg~m^{-3}\). Assign the material to the “SURF_1” (yellow) and “SURF_2” (orange). On the

SURFline change the back side boundary condition of one of the surfaces toINSULATEDand on the other toEXPOSED(See section 11.3.3 FDS User’s Guide). Assume aTHICKNESSof 10 mm (0.01 m). Analyse theWALL TEMPERATURE(on front surface) as well as theINSIDE WALL TEMPERATUREat depths 2.5 mm and 7.5 mm and theBACK WALL TEMPERATURE(on back surface) (see 21.2.1 and 21.2.3 FDS User’s Guide). For this purpose a respectiveDEVCmust be placed on the front surface of the solidOBSTRUCTION. The parameterIOR(Index of Orientation) is required for any device that is placed on the surface of a solid. It indicates the direction that the device points at. For example,IOR = -1means that the device is mounted on a wall that faces in the negative x direction. Run the simulation for 600 s and plot the indicated temperatures for both surfaces.At which timestep does the difference between the

WALL TEMPERATUREof both surfaces exceed a ratio of 5%?Assign

VOIDandEXPOSEDback wall boundary conditions to the respective surfaces and evaluate theTEMPERATUREat a gas phase cell directly behind the obstruction. Then extend the obstruction width to at least two cells and run the simulation again afterwards. Compare the measured temperatures. Make sure the devices are not within any obstruction as you change the width of the wall.

1. and 2. Solution

data_root = root + 'data/heat_transfer/HeatTransfer_2_1'

sim = fdsreader.Simulation(data_root)

time = sim.devices['Time'].data

steel_exposed_front = sim.devices['Steel_exposed_front'].data

steel_exposed_025 = sim.devices['Steel_exposed_025'].data

steel_exposed_075 = sim.devices['Steel_exposed_075'].data

steel_exposed_back = sim.devices['Steel_exposed_back'].data

steel_insulated_front = sim.devices['Steel_insulated_front'].data

steel_insulated_025 = sim.devices['Steel_insulated_025'].data

steel_insulated_075 = sim.devices['Steel_insulated_075'].data

steel_insulated_back = sim.devices['Steel_insulated_back'].data

fig, ax1 = plt.subplots()

ax1.plot(time, steel_exposed_front, label="Front, back. exposed", color='blue')

ax1.plot(time, steel_exposed_025, label="d = 2.5 mm, back. exposed", color='red')

ax1.plot(time, steel_exposed_075, label="d = 7.5 mm, back. exposed", color='green')

ax1.plot(time, steel_exposed_back, label="Back, back. exposed", color='yellow')

ax1.plot(time, steel_insulated_front, label="Front, back. insulated", color='blue', linestyle='--')

ax1.plot(time, steel_insulated_025, label="2.5 mm, back. insulated", color='red', linestyle='--')

ax1.plot(time, steel_insulated_075, label="7.5 mm, back. insulated", color='green', linestyle='--')

ax1.plot(time, steel_insulated_back, label="Back, back. insulated", color='yellow', linestyle='--')

ax1.set_xlabel("Time / s")

ax1.set_ylabel("Temperature / $^\circ C$")

ax1.set_xlim(0,10)

ax1.set_ylim(20,35)

ax1.legend(ncol=1, bbox_to_anchor=(1.1, 1), loc='upper left')

ax1.grid(axis='x', linestyle='--', alpha=0.5)

ax1.grid(axis='y', linestyle='--', alpha=0.5)

plt.savefig('figs/backings_start.svg', bbox_inches='tight')

error = (steel_insulated_front-steel_exposed_front)/steel_insulated_front*100

ax2 = ax1.twinx()

ax2.plot(time, error, label = "rel. Error", color='purple')

handles_1, labels_1 = ax1.get_legend_handles_labels()

handles_2, labels_2 = ax2.get_legend_handles_labels()

ax1.legend(handles_1+handles_2, labels_1+labels_2, ncol=1, bbox_to_anchor=(1.1, 1), loc='upper left')

ax2.set_ylabel("Rel. Error / %")

ax1.set_xlim(0,600)

ax2.set_ylim(0,20)

# ax1.set_ylim(20,600)

ax1.set_yticks(np.linspace(0,600,5))

ax2.set_yticks(np.linspace(0,20,5))

plt.grid(axis='y', linestyle='--', alpha=0.5)

plt.savefig('figs/backings_end.svg', bbox_inches='tight')

plt.close()

Fig. 6.20 WALL TEMPERATURE and INSIDE WALL TEMPERATURE at several depths inside the solid steel obstruction within the first 10 seconds seconds of heating phase#

Fig. 6.21 WALL TEMPERATURE and INSIDE WALL TEMPERATURE at several depths inside the solid steel obstruction within the first 600 seconds seconds of heating phase. The purple line indicates the relative error between an insulated and exposed backing boundary condition.#

data_root = root + 'data/heat_transfer/HeatTransfer_2_2'

sim = fdsreader.Simulation(data_root)

time = sim.devices['Time'].data

exposed_temp_1cell = sim.devices['exposed_temp'].data

void_temp_1cell = sim.devices['void_temp'].data

data_root = root + 'data/heat_transfer/HeatTransfer_2_3'

sim = fdsreader.Simulation(data_root)

exposed_temp_2cell = sim.devices['exposed_temp'].data

void_temp_2cell = sim.devices['void_temp'].data

plt.plot(time, exposed_temp_1cell, label="back. exposed, 1 cell", color='blue')

plt.plot(time, void_temp_1cell, label="back. void, 1 cell", color='red')

plt.plot(time, exposed_temp_2cell, label="back. exposed, 2 cells", color='blue', linestyle='--')

plt.plot(time, void_temp_2cell, label="back. void, 2 cells", color='red', linestyle='--')

plt.xlabel("Time / s")

plt.ylabel("Temperature / $^\circ C$")

plt.xlim(0,600)

plt.legend(loc='best')

plt.grid(linestyle='--', alpha=0.5)

plt.savefig('figs/two_cell_problem.svg', bbox_inches='tight')

plt.close()

3. Solution

Fig. 6.22 Comparison of heat conduction through a wall. The heat transfer into the space behind the wall is not computed if the obstruction is thicker than one cell.#

import numpy as np

import matplotlib.pyplot as plt

def density(p_20, t):

if 20 <= t <= 115:

p = p_20

elif 115 < t <= 200:

p = p_20 * (1-0.02*(t-115)/85)

elif 200 < t <= 400:

p = p_20 * (0.98 - 0.03*(t-200)/200)

elif 400 < t <= 1200:

p = p_20 * (0.95 - 0.07*(t-400)/800)

return p

def conductivity(t, how='upper'):

if how == 'upper':

k = 2-0.2451 * (t / 100) + 0.0107 * (t / 100)**2

elif how == 'lower':

k = 1.36 -0.136 * (t / 100) + 0.0057 *(t / 100)**2

return k

def specific_heat(t, humidity=0):

if 20 <= t <= 100:

cp = 900

elif 100 < t <= 200:

if humidity == 0:

cp = 900 + (t - 100)

elif humidity == 1.5:

if t <= 115:

cp = 1470

elif t > 115:

cp = 1470 + (1000-1470)/(200-115)*(t-115)

elif humidity == 3.0:

if t <= 115:

cp = 2020

elif t > 115:

cp = 2020 + (1000-2020)/(200-115)*(t-115)

elif 200 < t <= 400:

cp = 1000 + (t - 200) / 2

elif 400 < t <= 1200:

cp = 1100

return cp/1000

temp_array = np.arange(20, 1200,1)

density_array = [density(2400, t) for t in temp_array]

conductivity_upper_array = [conductivity(t, how='upper') for t in temp_array]

conductivity_lower_array = [conductivity(t, how='lower') for t in temp_array]

specific_heat_array_0 = [specific_heat(t, humidity=0.0) for t in temp_array]

specific_heat_array_15 = [specific_heat(t, humidity=1.5) for t in temp_array]

specific_heat_array_30 = [specific_heat(t, humidity=3.0) for t in temp_array]

plt.plot(temp_array, specific_heat_array_0, color='black', label="humidity 0%")

plt.plot(temp_array, specific_heat_array_15, color='black', linestyle='--', label="humidity 1.5%")

plt.plot(temp_array, specific_heat_array_30, color='black', linestyle=':', label="humidity 3%")

plt.xlabel("Temperature / $^\circ C$")

plt.ylabel("Specific Heat / $kJ~/~kg~K$")

plt.legend(loc='best')

plt.grid(True, linestyle='--', alpha=0.5)

plt.savefig("figs/specific_heat_capacity.svg")

plt.close()

plt.plot(temp_array, conductivity_upper_array, color='black', label="upper limit")

plt.plot(temp_array, conductivity_lower_array, color='black', linestyle='--', label="lower limit")

plt.xlabel("Temperature / $^\circ C$")

plt.ylabel("Conductivity / $W~/~m~K$")

plt.legend(loc='best')

plt.grid(True, linestyle='--', alpha=0.5)

plt.savefig("figs/conductivity.svg")

plt.close()

plt.plot(temp_array, density_array, color='black')

plt.xlabel("Temperature / $^\circ C$")

plt.ylabel("Density / $kg~/~m^3$")

plt.grid(True, linestyle='--', alpha=0.5)

plt.savefig("figs/density.svg")

plt.close()

Task 3#

The assumption of constant thermal material properties is a simplification that often is sufficiently accurate. In some cases, however, it may be necessary to consider the actual temperature-dependent properties of a material or component. This can be done in FDS by defining a RAMP function, which describes a material parameter as a function of temperature (see section 11.3.2 FDS User’s Guide).

Figure Fig. 6.24 - Fig. 6.26 shows the temperature-dependent relationships for the specific heat capacity, thermal conductivity and density of concrete according to DIN EN 1992-1-2.

Note

In FDS only the SPECIFIC_HEAT and CONDUCTIVITY can be ramped while DENSITY and EMISSIVITY cannot. Unlike the fractional specification, such as in the definition of the HRR curve, the material properties are defined as absolute values in the RAMP function.

Tasks

At 20°C, read the values from Fig. 6.24 - Fig. 6.26 and define a new material “concrete” with the corresponding material properties. Define another material taking into account the variable material properties. Therefore roughly map the corresponding progression curves using a RAMP function (max. 7 datapoints each). Assign the two materials to “SURF_1” and “SURF_2” in the FDS file.

Run the simulation for 600 s and compare the

WALL TEMPERATUREfor both surfaces as well as theINSIDE WALL TEMPERATUREat d = 10 mm. Assume the wall to have a thickness of 10 cm. Assume a humidity of 3 %. For the conductivity consider the upper limit.

Fig. 6.23 Namelist dependencies MATL (material) and RAMP (ramp function)#

Fig. 6.24 Density of concrete as a function of temperature#

Fig. 6.25 Specific heat of concrete with quartz-containing additive as a function of temperature#

Fig. 6.26 Thermal conductivity of concrete#

1. and 2. Solution

data_root = root + 'data/heat_transfer/HeatTransfer_3'

sim = fdsreader.Simulation(data_root)

time = sim.devices['Time'].data

concrete_1_surf = sim.devices['Concrete_1_surf'].data

concrete_2_surf = sim.devices['Concrete_2_surf'].data

concrete_1_ins = sim.devices['Concrete_1_ins'].data

concrete_2_ins = sim.devices['Concrete_2_ins'].data

plt.plot(time, concrete_1_surf, color='blue', label="WALL Temp. RAMP MAT")

plt.plot(time, concrete_2_surf, color='red', label="WALL Temp. FIXED MAT")

plt.plot(time, concrete_1_ins, color='blue', linestyle='--', label="INSIDE WALL Temp. RAMP MAT")

plt.plot(time, concrete_2_ins, color='red', linestyle='--', label="INSIDE WALL Temp. FIXED MAT")

plt.grid(axis='x', linestyle='--', alpha=0.5)

plt.xlabel("Time / s")

plt.ylabel("Temperature / $\circ^C$")

plt.grid(axis='y', linestyle='--', alpha=0.5)

plt.legend(loc='best')

plt.savefig('figs/mat_prop.svg')

plt.close()

Fig. 6.27 WALL TEMPERATURE and INSIDE WALL TEMPERATURE of concrete SURF with fixed and temperature dependent material properties#